Cabos de alimentação Fábrica

A principal empresa de arquitetura da China caixa de distribuição de energia , cabos eléctricos,caso da luz,controlador de guincho fábrica e fornecedores.

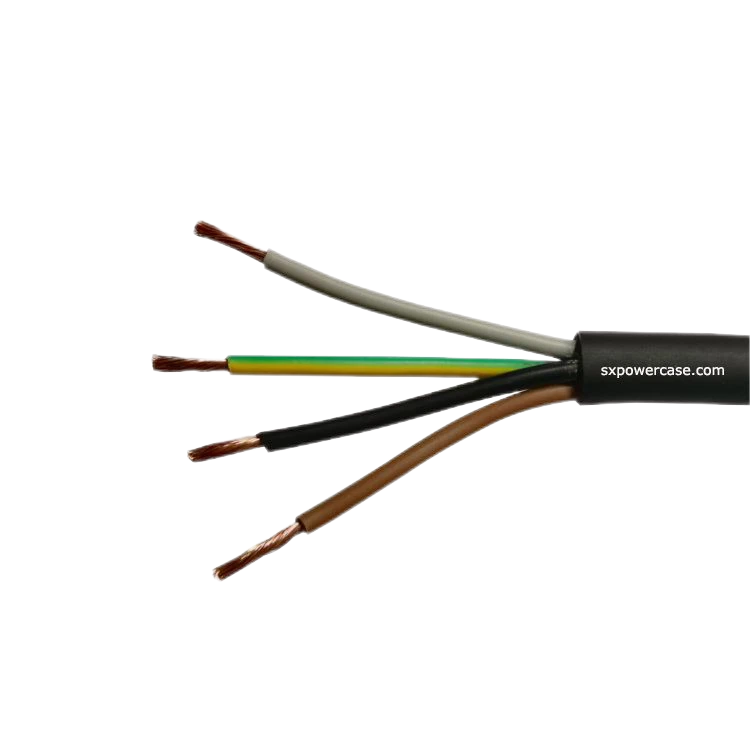

Tabela de tamanhos de cabos AWG

Podemos personalizar o cabo AWG de acordo com as necessidades do cliente, com ou sem ficha. O lado esquerdo é a nossa tabela de tamanhos

Fabrico

Melhor fábrica de cabos de alimentação na China

A nossa fábrica ocupa mais de 2000 metros quadrados no distrito de Panyu, na cidade de Guangzhou, e tem 2 oficinas diferentes para produtos diferentes, uma para caixas de voo e hardware, outra para caixas de distribuição de energia e itens relacionados, com 11-50 trabalhadores experientes, incluindo pessoas do QC, designers e executivos de vendas internacionais.

Forças produtivas

Servir

Área da fábrica

Porquê Escolha-nos

O nossoFábrica de cabos de alimentação

Serviços profissionais

A nossa fábrica ocupa mais de 2000 metros quadrados no distrito de Panyu, na cidade de Guangzhou, e tem 2 oficinas diferentes para produtos diferentes, uma para caixas de voo e hardware, outra para caixas de distribuição de energia e itens relacionados, com 11-50 trabalhadores experientes, incluindo pessoas do QC, designers e executivos de vendas internacionais.

Catálogo SX

Clientes Amor

Testemunho

O serviço da SX Power Case é absolutamente profissional! A minha experiência em lidar com eles foi super tranquila e foi muito fácil trabalhar com eles. Construíram as minhas distros exatamente como eu pedi. Quanto à qualidade, estou espantado! Não estava mesmo à espera de um trabalho tão profissional e detalhado. As caixas são bem construídas e os componentes são de boa qualidade. Quanto ao envio, demorou cerca de 3 meses, mas valeu a pena esperar! A encomenda foi muito bem embalada! Voltarei a fazer negócio com eles de certeza!

Dave HarrisRecomendo esta empresa 100%, o comercial que me atendeu respondeu a todas as minhas dúvidas muito rapidamente, mesmo com a diferença horária que temos ... Tenho mais entregas pendentes desta empresa e não tenho dúvidas que seria perfeito... a minha experiência tem sido muito satisfatória

David PedrosaOutros produtos

Ao conceber um produto original, tem o controlo total de todos os aspectos e permite a criatividade. A possibilidade de escolher cada pormenor significa possibilidades ilimitadas ao criar o seu novo desenho!

Controlador do guincho

Personalize o número de fichas, a tensão, os volts, a potência e o estilo de ficha do controlador do guincho de potência

Malas de voo

O tamanho da mala de voo pode ser personalizado. Nós desenhamos os desenhos e produzimo-los após confirmação.

Caixa de distribuição de energia

Podem ser personalizados vários tamanhos, potências e especificações, incluindo fichas e outros acessórios

Subscrever a newsletter

Envie o seu pedido de orçamento e responderemos no prazo de 24 horas

O nosso Últimas notícias

2026 Tet Holiday Announcement

2026 Tet Holiday Announcement As the 2026 Tet (Spring Festival) approaches, we would like to inform our valued customers and partners of our holiday schedule. Holiday Schedule Break Time:February 8, 2026 – February 25, 2026 During the Tet holiday, our team will be on break to celebrate this important traditional festival. Order & Production Arrangement […]

What Is a Power Distribution Rack?

What Is a Power Distribution Rack? A power distribution rack is a rack-mounted system that houses one or more power distribution units (PDUs), breakers and outlet panels, centralizing the delivery of mains power to multiple devices. In practice, this setup provides “space-saving power distribution in a flexible design”. For example, a PDU is defined as […]

O que é uma Power Distro Box?

O que é uma caixa de distribuição de energia? Porque é que os profissionais de eventos e os grossistas confiam nela Uma caixa de distribuição de energia - abreviatura de caixa de distribuição de energia - é um componente essencial na gestão do fornecimento seguro e eficiente de eletricidade em várias aplicações. Desde eventos ao ar livre em grande escala a locais de trabalho industriais, estas unidades permitem que uma única fonte de energia alimente várias saídas, cada uma [...]

O produto é de muito boa qualidade e bem feito. O design é perfeito e adequado ao meu projeto. O serviço foi excecional e a entrega atempada. Estou muito satisfeito no geral. Também estou muito satisfeito com o serviço de entrega.

Poly Dem